Since 2015, our Korean operating subsidiary has been subject to a set of GHG emissions regulations known as the Korean Emissions Trading Scheme (K-ETS). K-ETS sets a cap on the total amount of emission allowed from key sectors, encouraging businesses to adopt cleaner technologies and practices by making it financially beneficial to reduce their carbon footprint. Since the introduction of the K-ETS scheme, Magnachip has had a surplus of carbon credits every year, meaning we are able to ‘sell’ credits to other organizations.

GHG reduction efforts

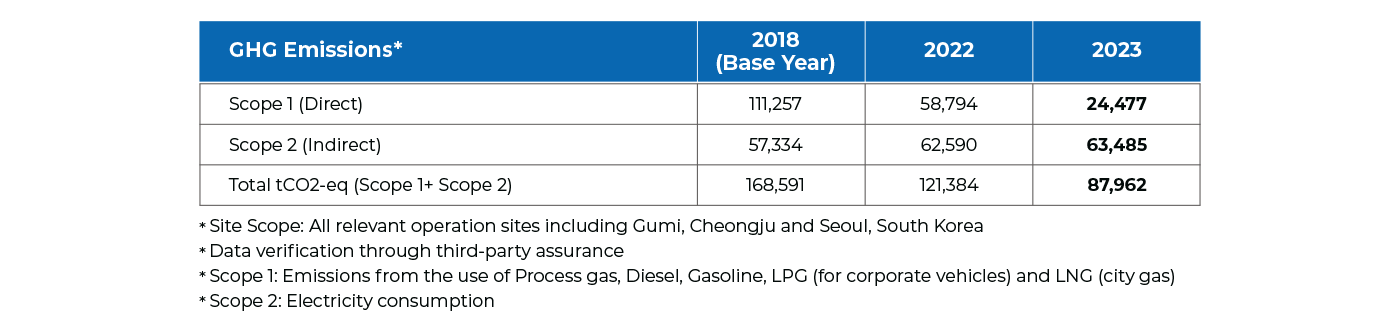

One of our most successful sustainability initiatives started in 2018, when we began the installation of plasma scrubbers at our manufacturing facility in Gumi. As shown by the figures below, the plasma scrubbers have helped us to dramatically cut our GHG emissions.

Stats: Impact of plasma scrubbers on our GHG emissions

Year of introduction: 2018

Number of operational scrubbers as of December 31, 2023: 38

Emissions in 2018: 168,591 tCO2

Emissions in 2022: 121,384 tCO2

Emissions in 2023: 87,962 tCO2

Total reduction since 2018: 80,629 tCO2

To help steer sustainability decision-making, capital expenditure figures relating to the plasma scrubbers are reported to the Board for review and approval.

Table 2: Magnachip GHG emissions

Air pollution management

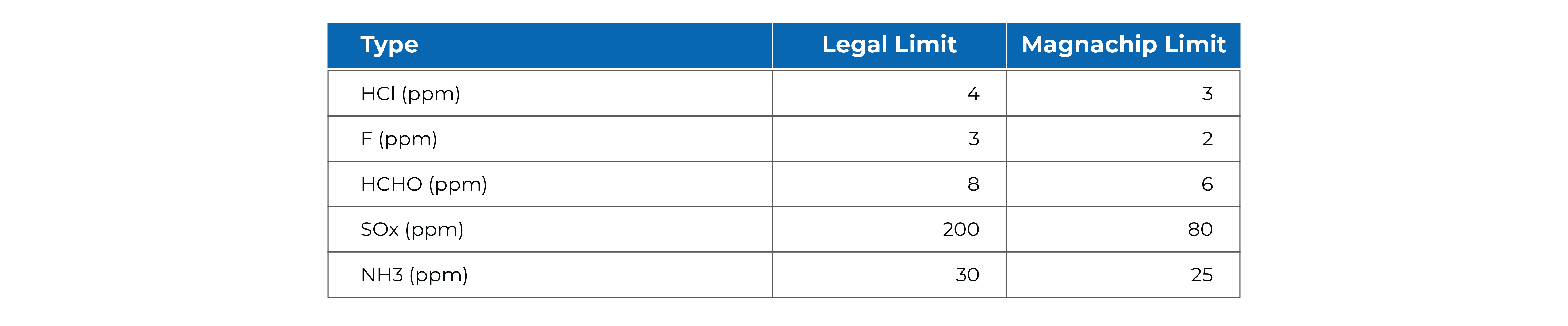

We classify air pollutants emitted from our semiconductor manufacturing processes as either acid, toxic or organic, and keep their average concentration below our internally set targets, which are more stringent than the legal limits.

Among the pollutants regulated under Korean law, our ESH Team currently manages 13 pollutants emitted by our operations. We have selected five for our current disclosure, as shown in the table below: Hydrogen Chloride (HCI), Fluorinated greenhouse gases (F), Formaldehyde (HCHO), Sulphur Oxides (SOx), and Ammonia (NH3).

Table 3: Magnachip air pollutants

Energy consumption and conservation

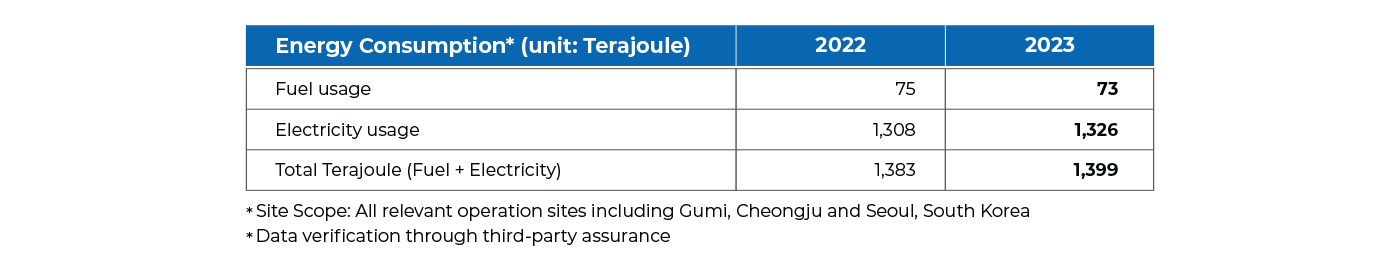

The following table shows our energy consumption for the periods presented, calculated in accordance with environmental legislation.

Table 4: Magnachip energy usage 2022-23

We monitor our energy consumption and set reduction targets through annual EIAs, and we assess our implementation progress through quarterly compliance evaluations. Energy reduction performance is reported to senior management by the ESH Team every year. As shown in the table above, our total energy consumption was 1,383 terajoules in 2022 and 1,399 terajoules in 2023.

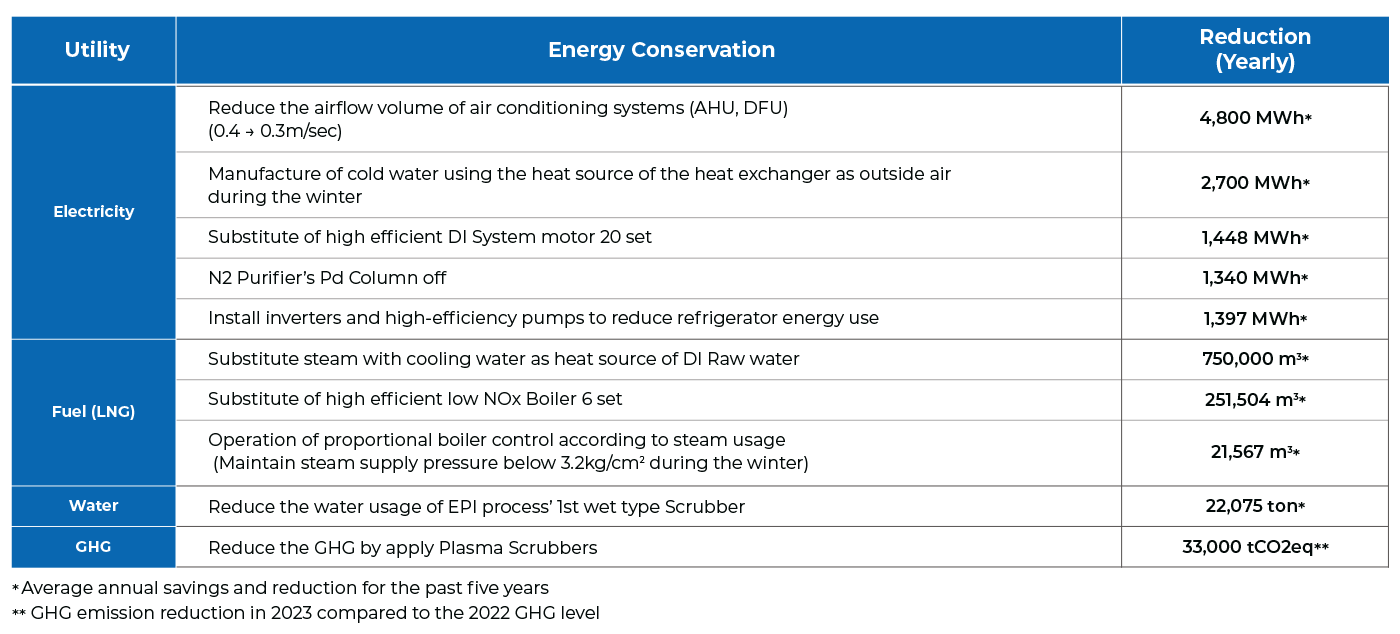

We have introduced a range of energy conservation measures as summarized in the table below, and we hold regular internal meetings to discuss implementation, monitor performance and secure funding for new initiatives. These measures include, but are not limited to:

Table 5: Energy conservation measures