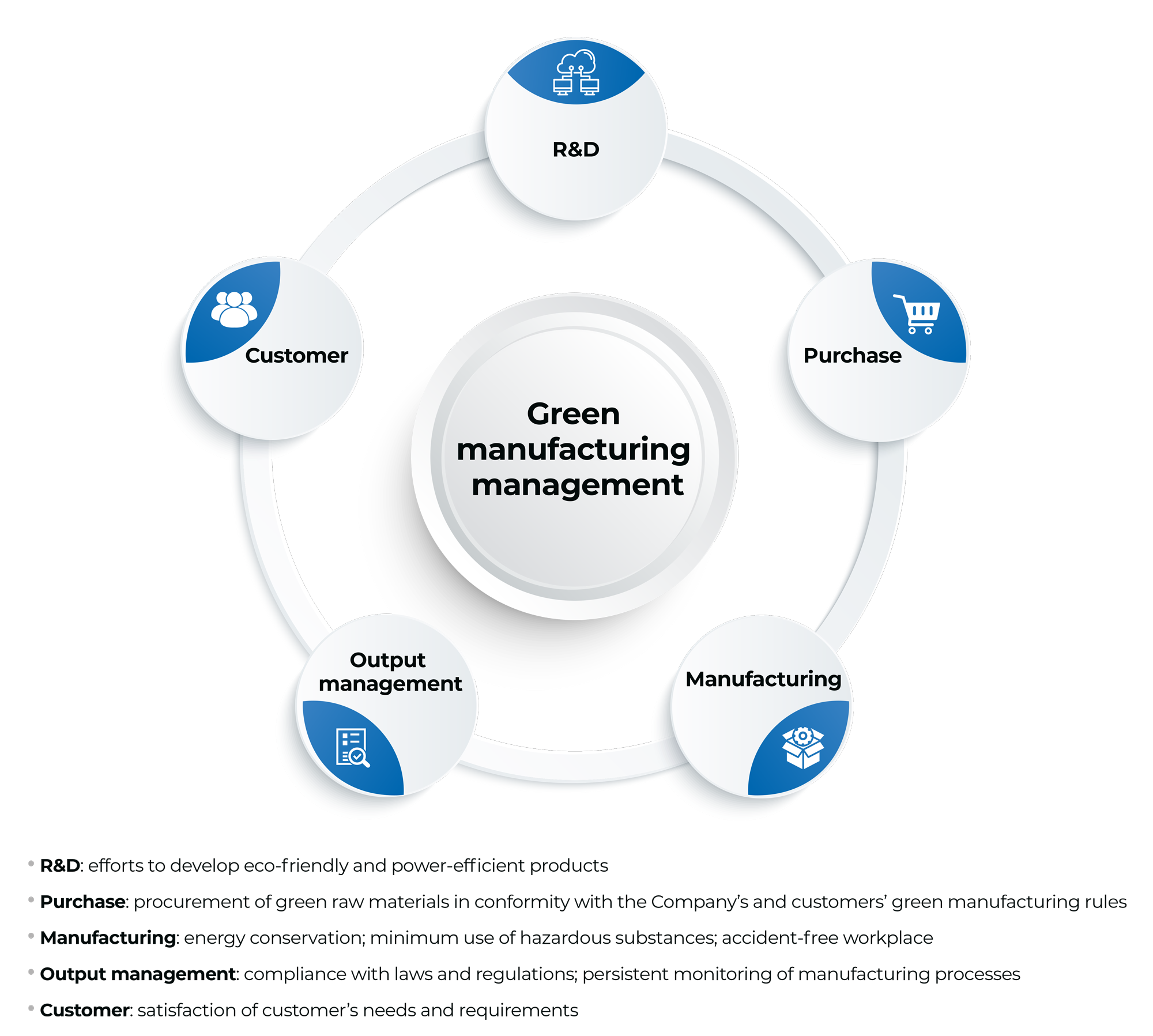

Green Manufacturing Management

We are committed to minimizing our environmental impact and strive to make our products and services as sustainable as possible.

In light of this, and in order to meet our international and domestic compliance commitments, we have created the “Green Manufacturing Management Rule”, which we apply to all the products we design, build and deliver to our customers. This rule enables product traceability through the setting of continuous indicators and goals. It also ensures that sustainability remains a top priority throughout all stages of the product lifecycle, as shown in the diagram below.

Diagram 5: Green manufacturing management

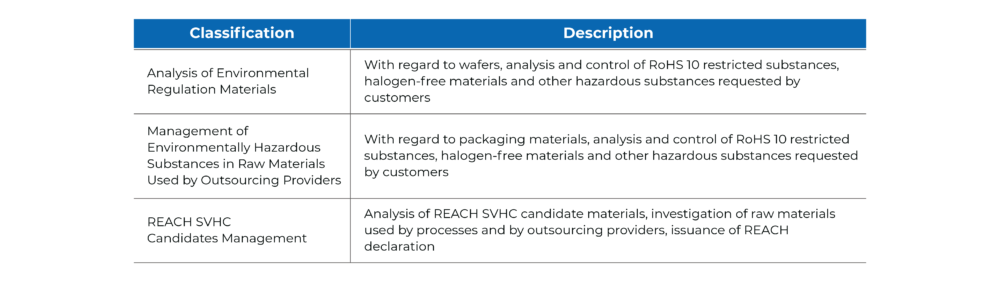

Table 7: Overview of green analysis and management

Hazardous substances

The “Green Manufacturing Management Rule” also stipulates that our products should not contain environmentally hazardous substances. This means we use controlled environmental toxins only within applicable limits, and that our products do not contain IEC 62474.

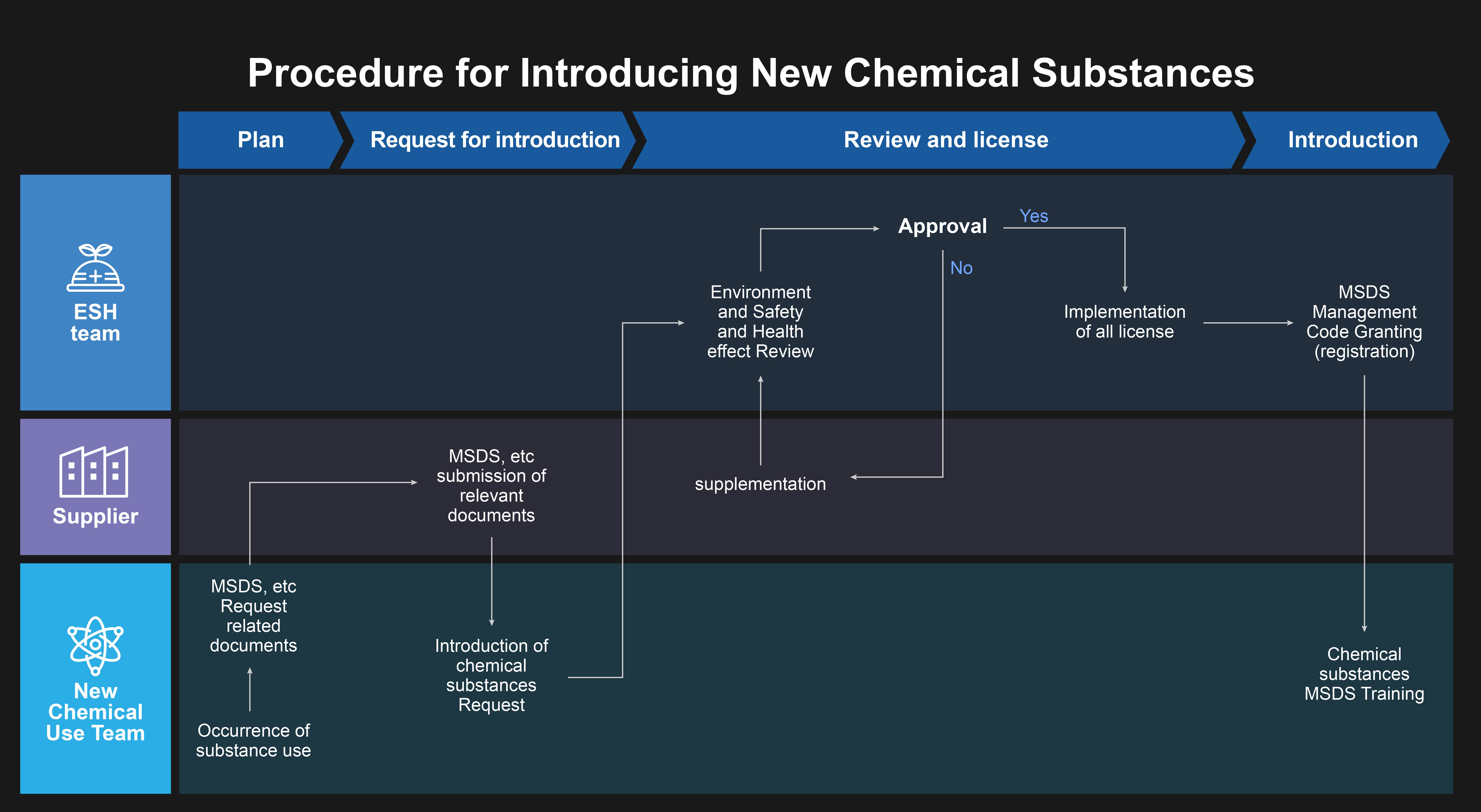

Before introducing hazardous substances into our processes, we screen incoming chemicals through a detailed evaluation system, verifying their environmental compliance in accordance with our pre-approval policy.

The following policies outline our procedures and responsibilities in relation to hazardous chemicals:

Life-cycle assessments

We conduct annual life-cycle assessments (LCAs) to monitor the long-term environmental impact of our production activities. Through internal EIAs, we also analyze the impact of certain raw materials, and the energy required to manufacture our products.

Quality management

We aim to provide outstanding products and services that deliver excellent value for our customers. To that end, we remain focused on continuous improvement through the application of a comprehensive quality management system. For more information on our approach, please refer to the following reports: